Maintaining a car lift is not simply an option; it is a necessary practice that ensures the safety, reliability, and longevity of this essential piece of automotive equipment. Various types of car lifts, such as those from BendPak, Mohawk Lifts, Atlas Lifts, and Challenger Lifts, serve as vital tools in workshops. Regular maintenance extends not only the life of the lift but also improves the efficiency of the services performed using it. Proper care involves diligent inspections, lubrication, and adherence to safety standards, which are crucial in avoiding costly breakdowns and ensuring uninterrupted operations.

Understanding the Mechanics of Car Lifts for Better Maintenance

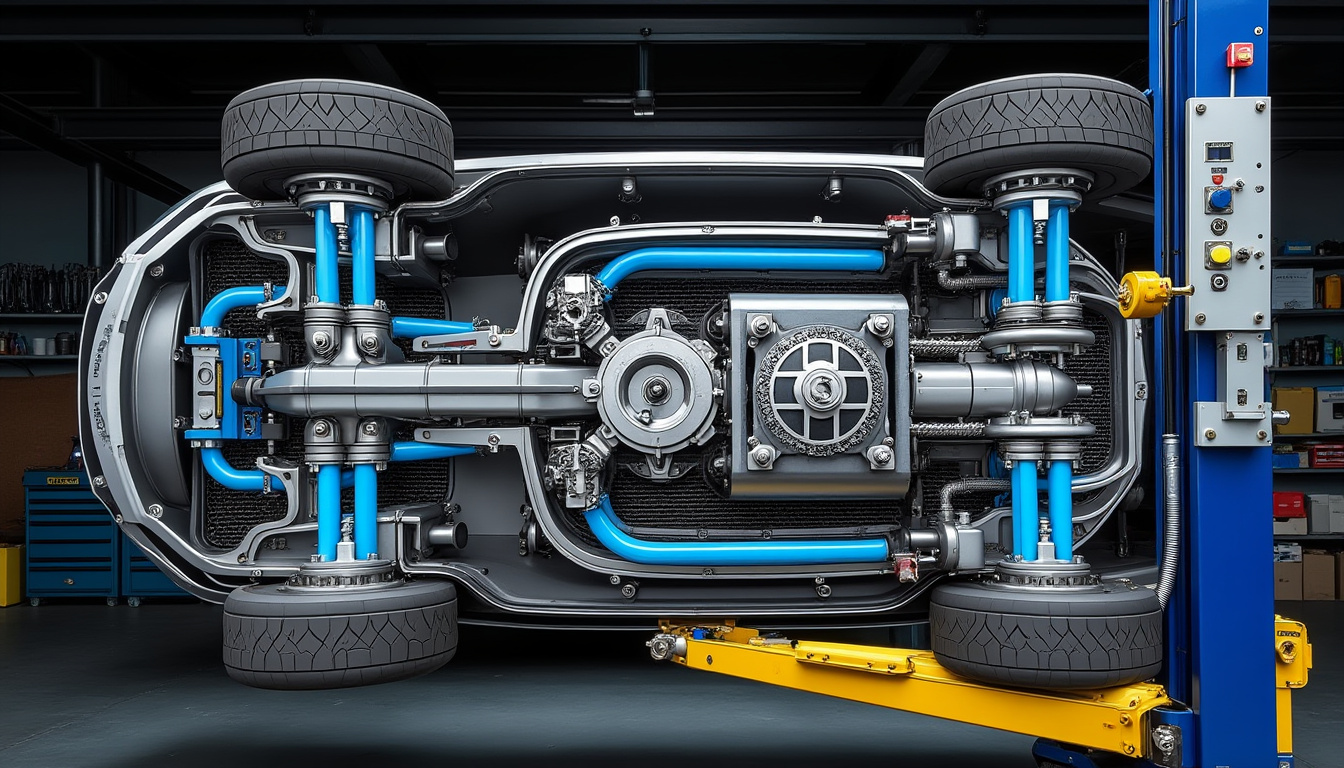

To effectively maintain a car lift, gaining a basic understanding of its workings is essential. Car lifts primarily operate through hydraulic or mechanical systems. Hydraulic lifts use fluid pressure to raise and lower vehicles, while mechanical lifts, like screw lifts, rely on mechanical advantage principles. Each system presents unique maintenance needs and challenges.

Types of Car Lifts: Common Varieties and Their Maintenance Needs

The automotive market features several types of lifts, including:

- 2-Post Lifts: Commonly used in garages for their versatility.

- 4-Post Lifts: Typically chosen for their stability, excellent for heavy-duty applications.

- Scissor Lifts: Known for their compact design, perfect for low-clearance areas.

- Portable Lifts: Offer flexibility and can be moved as needed.

Each type requires specific maintenance practices. For instance, 2-post lifts may necessitate more frequent inspections due to their complex hydraulic system. This allows for easier access to critical components that could wear over time. A thorough inspection and timely lubrication of the hydraulic system on lifts from brands like Rotary Lifts or Tuxedo Lifts help in maintaining optimal performance.

Regular Inspections: A Key to Longevity

Every car lift requires routine inspections to identify signs of wear or faults before they lead to failures. Technicians should perform the following checks routinely:

- Inspect the hydraulic hoses for leaks.

- Check for any rust on the frame and structural components.

- Test the safety systems, including limit switches and emergency stops.

- Examine the lift platform for signs of wear or damage.

Regular inspections help to ensure all components operate as intended, which is critical for both safety and equipment longevity. For further resources on conducting effective inspections, refer to this detailed maintenance guide.

Daily Maintenance Practices to Enhance Performance

Establishing a daily routine for car lift maintenance is invaluable in extending its operational life. Quick checks can often prevent major repairs and save costs. Key daily tasks include:

- Visual inspection of the lift for any obvious signs of damage.

- Verification of hydraulic fluid levels and topping off if necessary.

- Cleaning the lift to prevent debris accumulation that can hinder operation.

Commencing each workday with these checks encourages a culture of safety and care within the workshop environment. The results of diligent daily maintenance often translate into longer-lasting equipment.

Essential Lubrication Techniques For Your Car Lift

Lubricating the moving parts of the lift is essential for smooth operation. Various components, such as sliding surfaces and pivots, require regular lubrication to minimize friction and wear. Applying the right type of lubricant to the correct locations can significantly improve lift performance.

| Component | Recommended Lubricant | Frequency of Application |

|---|---|---|

| Hydraulic Cylinders | Hydraulic fluid | Monthly |

| Pivot Points | Grease | Every 3 months |

| Sliding Rails | Silicone spray | Every week |

Understanding the lubrication requirements of different lifts, whether it be LiftMaster or APlusLift, can create a substantial positive impact on overall lift performance. Regularly adhering to lubrication schedules will minimize wear and provide a smoother operational flow.

Safety Protocols for Car Lift Usage and Maintenance

Safety is paramount when operating a car lift. Implementing and adhering to safety protocols can prevent accidents and ensure that equipment is used properly. Some essential safety practices include:

- Always verify that the lift is on level ground before engaging.

- Ensure that safety locks are engaged when lifting.

- Keep the area around the lift clear of obstructions.

- Train all personnel on the correct procedures for using the lift.

Following these practices not only safeguards operators but also contributes to the longevity of the equipment itself. Familiarity with safety measures directly influences the overall lifespan of the lift and reduces liability in a workshop environment.

The Role of Manufacturer Guidelines

Adhering to the manufacturer’s maintenance schedule is critical. Each lift brand, whether it be Coats or Atlas Lifts, provides specific guidelines regarding inspections, lubrication needs, and operational protocols. These guidelines are developed based on testing and engineering insights.

It is advisable to maintain a documented maintenance log that includes completed inspections, repairs, and lubrication activities. Such records can be tremendously beneficial, especially during audits or inspections. For more information on following manufacturer recommendations, explore the comprehensive guide available here.

Dealing with Repairs and Troubleshooting Common Issues

Failures can occur despite the most diligent maintenance practices. Recognizing common issues quickly allows for faster resolutions. Some typical problems that may arise include:

- Hydraulic leaks: These can be caused by deterioration or damage to hydraulic hoses or seals.

- Unresponsive safety locks: This can result from mechanical issues or insufficient maintenance.

- Poor lift performance: Often related to inadequate lubrication or dirty components.

Troubleshooting these issues typically requires a systematic approach to identify and rectify faults. Comprehensive troubleshooting guides can often be found through specific manufacturers like Rotary Lifts and Tuxedo Lifts. Employing the correct method for addressing potential problems can drastically reduce downtime.

When to Call a Professional Technician

While many maintenance tasks can be performed in-house, there are moments when calling a professional technician is essential. Complex repairs, such as hydraulic repairs or extensive electronic issues, often require specialized knowledge and tools.

Recognizing the limits of in-house capabilities can save time and prevent safety hazards. Establishing a relationship with a reputable service provider ensures that support is available whenever required, and prevents complete operational halts in your workshop.

Seasonal Checks: Adapting Maintenance to Changing Conditions

Different seasons can affect the performance and requirements of car lifts. Regular seasonal checks should be integrated into the maintenance routine to adapt to environmental changes:

- Winter: Ensure that hydraulic fluids are suitable for lower temperatures.

- Summer: Check for excessive debris and overheating, as heat may affect hydraulic systems.

- Spring and Fall: Conduct thorough inspections to prepare for increased workload and changes in usage patterns.

Addressing seasonal requirements helps ensure that lifts remain functional year-round. Consistency in seasonal maintenance also supports overall equipment health and longevity.

Creating a Comprehensive Maintenance Schedule

Crafting a detailed maintenance schedule can streamline the upkeep process. A suggested framework may include:

| Task | Frequency | Notes |

|---|---|---|

| Inspect hydraulic system | Monthly | Look for leaks or wear |

| Lubricate key parts | Quarterly | Refer to lubrication guide |

| Comprehensive safety check | Biannually | Involve all staff for training |

Developing a consistent schedule ensures that lift maintenance becomes a habitual practice, ultimately enhancing longevity. Consistent monitoring reduces the chances of unexpected failures and costly repairs.

Conclusion: The Future of Car Lift Maintenance

As technology evolves, so too do the maintenance practices associated with car lifts. Innovations in smart technology may enable more efficient monitoring and predictive maintenance, thereby transforming how operators approach lift care. Staying informed and adaptable can profoundly affect not only the longevity of car lifts but also the overall efficiency of operations in any workshop.

For additional reading on lift maintenance innovations, explore comprehensive discussions in the automotive community and stay ahead of the curve.

My name is Mark, and I am 42 years old. I am a technical writer specializing in automotive lifting equipment. With 20 years of experience in the automotive industry, including 10 years dedicated to lifting equipment, I leverage my expertise to ensure clarity and technical accuracy. Passionate about my field, I am committed to delivering high-quality and informative content.