Maintaining a car lift’s hydraulic system is crucial for ensuring the safety and efficiency of automotive workshops. Car lifts are indispensable tools in the automotive repair industry, enabling technicians to perform vital services. However, when hydraulic systems fail, the consequences can be dire. This article explores the common causes of hydraulic failures in car lifts, offers insights into effective troubleshooting methods, and emphasizes the importance of regular maintenance.

Understanding Hydraulic System Functionality

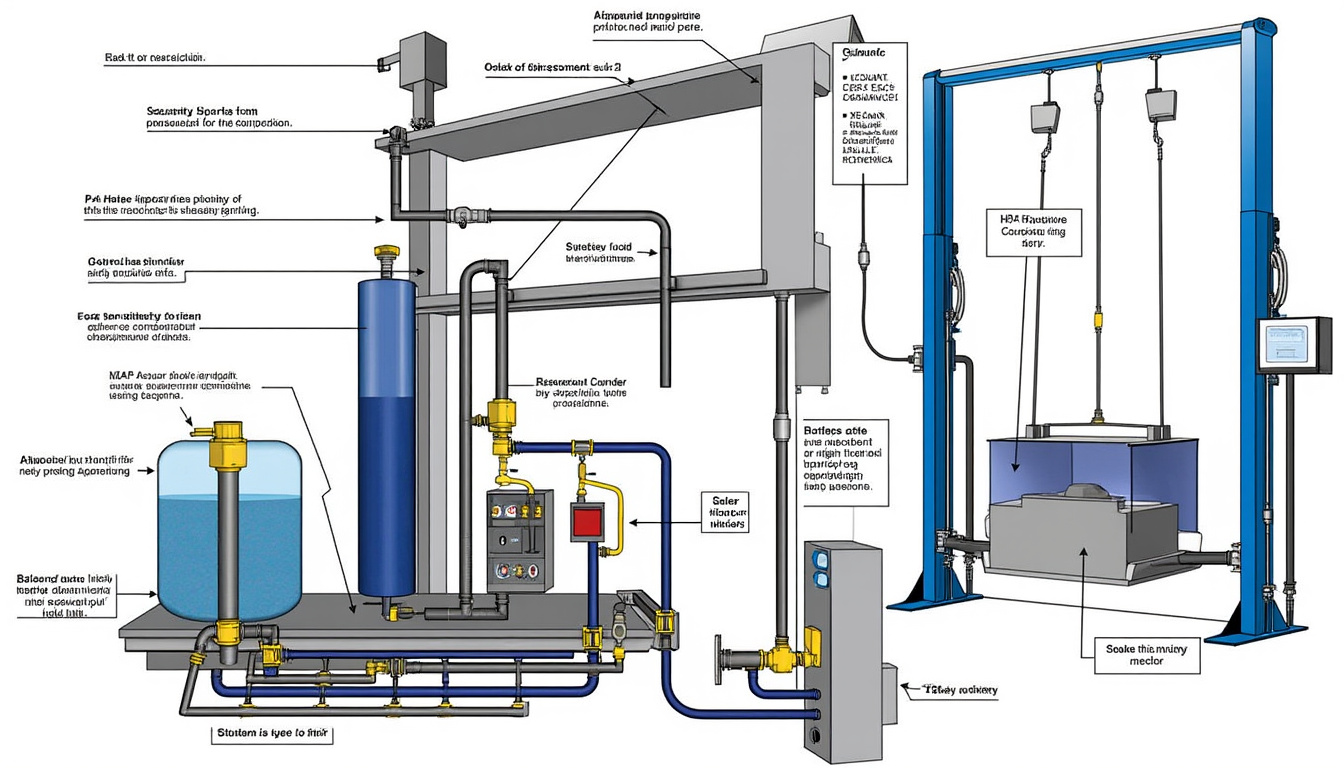

The hydraulic system in a car lift operates on the principle of fluid mechanics, utilizing pressurized hydraulic fluid to lift and lower vehicles safely. Understanding how these systems function helps identify potential failure points. A typical hydraulic lift comprises several key components, including the hydraulic cylinder, pump, actuator, and valves.

Key Components of Hydraulic Systems

The integrity of each component is vital for the overall functionality of the lift. Let’s break down each major component:

- Hydraulic Cylinder: The heart of the system, it converts hydraulic energy into mechanical force.

- Hydraulic Pump: Responsible for generating pressure in the hydraulic fluid.

- Actuator: Controls the movement of the lift arms based on user input.

- Hydraulic Fluid: Transfers energy throughout the system; its condition is paramount for optimal performance.

Common Failure Points

Several issues can lead to hydraulic system failures, including:

- Fluid Leaks: A primary cause of hydraulic failures. Check for leaks at seals, hoses, and connections.

- Contaminated Fluid: Dirt and debris can cause blockages and wear in the system.

- Aging Components: Over time, seals and hoses can become worn, leading to catastrophic failures.

The Role of Regular Maintenance

Routine maintenance is essential for preventing hydraulic failures in car lifts. By establishing an effective maintenance schedule, repair shops can significantly reduce the risk of breakdowns and ensure safe operating conditions. Here are key maintenance practices:

- Daily Inspections: Inspect hoses, connections, and hydraulic fluid levels for any visible issues.

- Fluid Changes: Replace hydraulic fluid periodically to maintain cleanliness and functionality.

- Component Checks: Regularly examine the condition of seals, hoses, and fittings for signs of wear.

Creating a Maintenance Schedule

Implementing a maintenance schedule can help streamline these practices:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Daily | Check for apparent damages, leaks, or issues. |

| Fluid Level Check | Weekly | Ensure the fluid is at appropriate levels. |

| Hose Inspection | Monthly | Check hoses for wear, cracks, or leaks. |

| Fluid Change | Annually | Replace old fluid with fresh hydraulic fluid. |

Identifying Common Hydraulic Failures

Identifying issues within a hydraulic system can be challenging, as many failures are not immediately apparent. Here are typical symptoms that indicate hydraulic failure:

- Lift Will Not Move: This could result from insufficient hydraulic fluid.

- Fluid Leaks: Visible leaks around hoses or the hydraulic cylinder require immediate attention.

- Erratic Movement: If the lift raises or lowers unevenly, it suggests air in the hydraulic lines or contaminated fluid.

Troubleshooting Steps for Hydraulic Failures

When a hydraulic lift exhibits any of these symptoms, it is vital to troubleshoot promptly. Here’s a systematic approach:

- Check Fluid Levels: Ensure that the hydraulic fluid is at the recommended level.

- Inspect for Leaks: Look for signs of leakage, especially around seals and joints.

- Bleed the System: To remove trapped air from the hydraulic line, it might be necessary to bleed the system.

- Monitor the Pump: Listen for unusual noises from the hydraulic pump that may indicate internal wear.

Thorough troubleshooting can prevent further damage and maintain safety in the workshop.

Deep Dive into Hydraulic Cylinder Repair

In many cases, the hydraulic cylinder is the cause of failures. Understanding its mechanisms can aid in preventative maintenance and repairs. The hydraulic cylinder’s role is pivotal, converting hydraulic energy into mechanical force.

Common Issues with Hydraulic Cylinders

Several issues can affect the performance of hydraulic cylinders:

- Seal Damage: Once seals deteriorate, they can lead to fluid leaks, which compromise pressure.

- Corrosion: Corroded cylinders can weaken the structure over time.

- Worn Piston Rods: Excessive wear can affect sealing and function.

Repairing Hydraulic Cylinders

To address failures in hydraulic cylinders, consider the following repair steps:

- Disassemble the Cylinder: Carefully take apart the cylinder to access the inner components.

- Inspect Components: Look for signs of wear, corrosion, or damage.

- Replace Seals: Install new seals where necessary, ensuring compatibility with the hydraulic fluid.

- Reassemble and Test: After repairs, it’s crucial to reassemble the cylinder and conduct tests to ensure proper function.

Evaluating Lift Brand Performance: A Comparative Overview

Brands like BendPak, Atlas, and Snap-on are known for producing reliable hydraulic lifts. Understanding their performance can guide purchasing decisions when looking for durable equipment.

| Brand | Key Features | Ideal Use |

|---|---|---|

| BendPak | Durable construction, high weight capacity | Intensive automotive workshops |

| Atlas | Compact design, user-friendly | Residential garages and light use |

| Snap-on | High-end technology, long warranties | Professional repairs and custom builds |

Investing in Safety Enhancements

Safety should be paramount when working with hydraulic systems. Investing in safety features can dramatically reduce the risk of accidents associated with car lifts.

Essential Safety Features

Consider enhancements such as:

- Emergency Stop Buttons: Instantly halts lift operation during an emergency.

- Safety Cables: Prevents the lift from falling if hydraulic systems fail.

- Locking Latches: Ensures stability during operation.

Final Checks Before Use

Before operating a hydraulic lift, conducting final checks can prevent accidents:

- Confirm Fluid Levels: Ensure that the hydraulic fluid is topped off.

- Inspect Load Balance: Inspect vehicle placement to ensure stability.

- Test Controls: Ensure all controls are operational and responsive.

By conducting comprehensive checks and repairs, automotive technicians can promote a safe and efficient working environment.

In conclusion, understanding the mechanics behind hydraulic systems, recognizing common failure points, and implementing rigorous maintenance practices are essential for ensuring optimal performance of car lifts in various settings. Regular inspections, troubleshooting cycles, and awareness of safety features can enhance workplace safety and operational efficiency across automotive repair shops.

My name is Mark, and I am 42 years old. I am a technical writer specializing in automotive lifting equipment. With 20 years of experience in the automotive industry, including 10 years dedicated to lifting equipment, I leverage my expertise to ensure clarity and technical accuracy. Passionate about my field, I am committed to delivering high-quality and informative content.